Maximizing Efficiency: How to Choose the Right Compartment Air Filter for Your Industrial Equipment

Release time:

2024-07-04

**Introduction** In the world of industrial equipment, the importance of choosing the right compartment air filter cannot be overstated. Compartment air filters play a crucial role in maintaining the efficiency and performance of machinery by ensuring that the air entering the system is clean and free of contaminants. In this article, we will explore the key factors to consider when choosing a com

**Introduction**

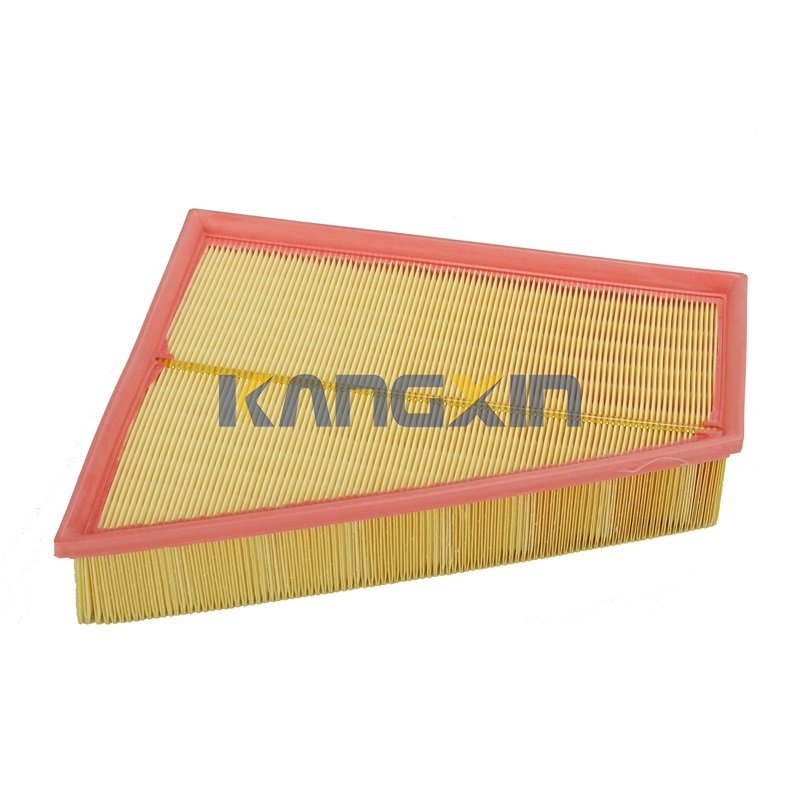

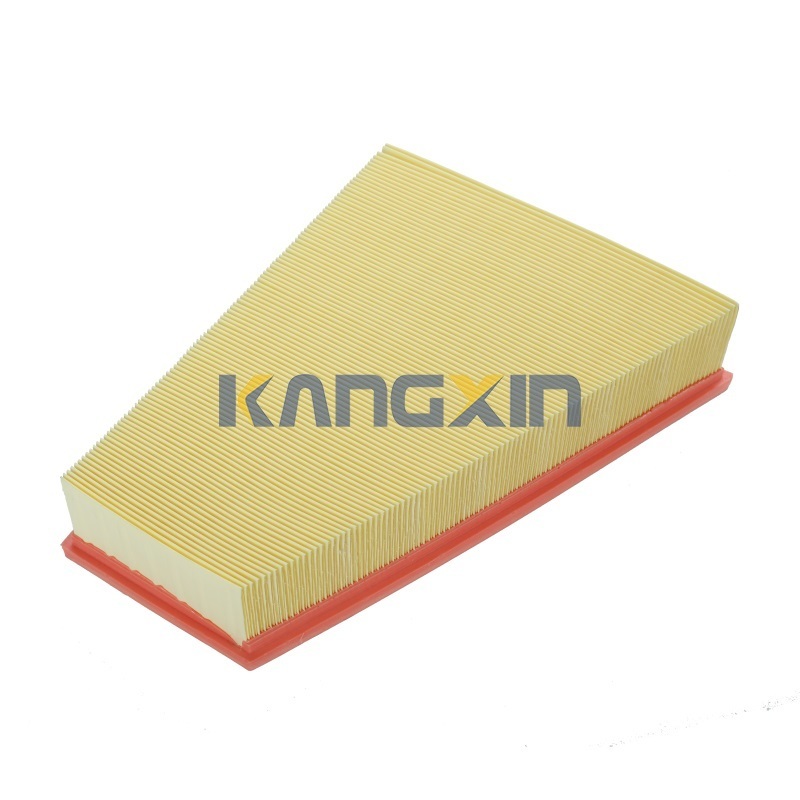

In the world of industrial equipment, the importance of choosing the right compartment air filter cannot be overstated. Compartment air filters play a crucial role in maintaining the efficiency and performance of machinery by ensuring that the air entering the system is clean and free of contaminants. In this article, we will explore the key factors to consider when choosing a compartment air filter for your industrial equipment to maximize efficiency and longevity.

**Understanding the Importance of Compartment Air Filters**

Compartment air filters are essential components of industrial equipment as they prevent dust, dirt, and other contaminants from entering the machinery and causing damage. By trapping particles in the air, compartment air filters help to extend the life of the equipment and improve its overall performance. Additionally, clean air filters can lead to increased energy efficiency and reduced maintenance costs.

**Factors to Consider When Choosing a Compartment Air Filter**

1. **Airflow Requirements**: One of the most important factors to consider when selecting a compartment air filter is the airflow requirements of your industrial equipment. Make sure to choose a filter that can handle the volume of air required for optimal performance.

2. **Efficiency Rating**: Look for compartment air filters with a high efficiency rating to ensure that they can effectively remove contaminants from the air. Filters with a higher efficiency rating will provide better protection for your equipment and improve its overall performance.

3. **Filter Media**: The type of filter media used in a compartment air filter can have a significant impact on its performance. Choose a filter with media that is designed to capture the specific contaminants present in your industrial environment.

4. **Size and Compatibility**: Ensure that the compartment air filter you choose is the correct size and compatible with your industrial equipment. A filter that is too small or incompatible with your machinery may not provide adequate protection.

5. **Maintenance Requirements**: Consider the maintenance requirements of the compartment air filter, including how often it needs to be replaced or cleaned. Choose a filter that is easy to maintain to ensure optimal performance and longevity.

**FAQs**

1. **How often should I replace my compartment air filter?**

- It is recommended to replace your compartment air filter according to the manufacturer's guidelines, typically every 6-12 months.

2. **Can I clean and reuse a compartment air filter?**

- Some compartment air filters are designed to be cleaned and reused, while others are disposable. Check the manufacturer's instructions for guidance.

3. **What are the benefits of using a high-efficiency compartment air filter?**

- High-efficiency compartment air filters can provide better protection for your industrial equipment, improve its performance, and reduce maintenance costs.

4. **How do I know if my compartment air filter needs to be replaced?**

- Signs that your compartment air filter needs to be replaced include reduced airflow, increased energy consumption, and visible dirt or damage on the filter.

5. **Are there different types of compartment air filters available?**

- Yes, there are various types of compartment air filters available, including pleated filters, HEPA filters, and activated carbon filters, each designed for specific applications.

**Conclusion**

Choosing the right compartment air filter for your industrial equipment is essential for maximizing efficiency and performance. By considering factors such as airflow requirements, efficiency rating, filter media, size, compatibility, and maintenance requirements, you can select a filter that will protect your machinery and extend its lifespan. Keep these key considerations in mind when choosing a compartment air filter to ensure optimal performance and longevity for your industrial equipment.

In the world of industrial equipment, the importance of choosing the right compartment air filter cannot be overstated. Compartment air filters play a crucial role in maintaining the efficiency and performance of machinery by ensuring that the air entering the system is clean and free of contaminants. In this article, we will explore the key factors to consider when choosing a compartment air filter for your industrial equipment to maximize efficiency and longevity.

**Understanding the Importance of Compartment Air Filters**

Compartment air filters are essential components of industrial equipment as they prevent dust, dirt, and other contaminants from entering the machinery and causing damage. By trapping particles in the air, compartment air filters help to extend the life of the equipment and improve its overall performance. Additionally, clean air filters can lead to increased energy efficiency and reduced maintenance costs.

**Factors to Consider When Choosing a Compartment Air Filter**

1. **Airflow Requirements**: One of the most important factors to consider when selecting a compartment air filter is the airflow requirements of your industrial equipment. Make sure to choose a filter that can handle the volume of air required for optimal performance.

2. **Efficiency Rating**: Look for compartment air filters with a high efficiency rating to ensure that they can effectively remove contaminants from the air. Filters with a higher efficiency rating will provide better protection for your equipment and improve its overall performance.

3. **Filter Media**: The type of filter media used in a compartment air filter can have a significant impact on its performance. Choose a filter with media that is designed to capture the specific contaminants present in your industrial environment.

4. **Size and Compatibility**: Ensure that the compartment air filter you choose is the correct size and compatible with your industrial equipment. A filter that is too small or incompatible with your machinery may not provide adequate protection.

5. **Maintenance Requirements**: Consider the maintenance requirements of the compartment air filter, including how often it needs to be replaced or cleaned. Choose a filter that is easy to maintain to ensure optimal performance and longevity.

**FAQs**

1. **How often should I replace my compartment air filter?**

- It is recommended to replace your compartment air filter according to the manufacturer's guidelines, typically every 6-12 months.

2. **Can I clean and reuse a compartment air filter?**

- Some compartment air filters are designed to be cleaned and reused, while others are disposable. Check the manufacturer's instructions for guidance.

3. **What are the benefits of using a high-efficiency compartment air filter?**

- High-efficiency compartment air filters can provide better protection for your industrial equipment, improve its performance, and reduce maintenance costs.

4. **How do I know if my compartment air filter needs to be replaced?**

- Signs that your compartment air filter needs to be replaced include reduced airflow, increased energy consumption, and visible dirt or damage on the filter.

5. **Are there different types of compartment air filters available?**

- Yes, there are various types of compartment air filters available, including pleated filters, HEPA filters, and activated carbon filters, each designed for specific applications.

**Conclusion**

Choosing the right compartment air filter for your industrial equipment is essential for maximizing efficiency and performance. By considering factors such as airflow requirements, efficiency rating, filter media, size, compatibility, and maintenance requirements, you can select a filter that will protect your machinery and extend its lifespan. Keep these key considerations in mind when choosing a compartment air filter to ensure optimal performance and longevity for your industrial equipment.

Keywords:

More information