All You Need to Know About Cabin Air Filter for Air Conditioning in Industrial Equipment

Release time:

2024-07-01

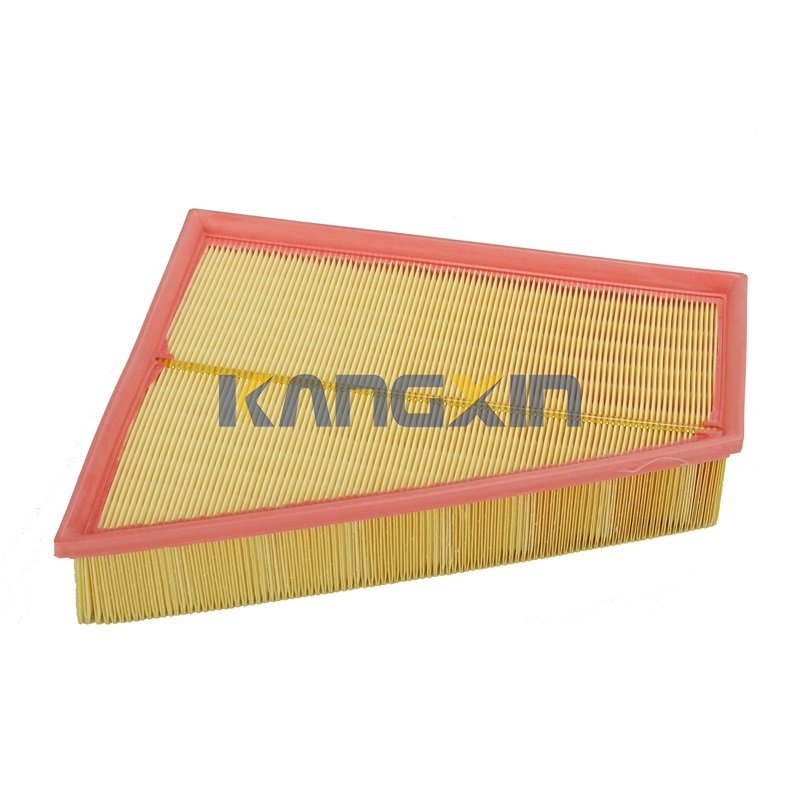

In the industrial equipment sector, cabin air filters play a crucial role in maintaining a clean and healthy environment inside machinery cabins. When it comes to air conditioning systems, a properly functioning cabin air filter is essential for ensuring the quality of indoor air. Cabin air filters are designed to trap dust, pollen, and other airborne particles before they enter the air condition

In the industrial equipment sector, cabin air filters play a crucial role in maintaining a clean and healthy environment inside machinery cabins. When it comes to air conditioning systems, a properly functioning cabin air filter is essential for ensuring the quality of indoor air.

Cabin air filters are designed to trap dust, pollen, and other airborne particles before they enter the air conditioning system. By doing so, they prevent these contaminants from circulating throughout the cabin, protecting both the equipment and the operators from potential health hazards. Regularly replacing the cabin air filter is important to ensure optimal performance and efficiency of the air conditioning system.

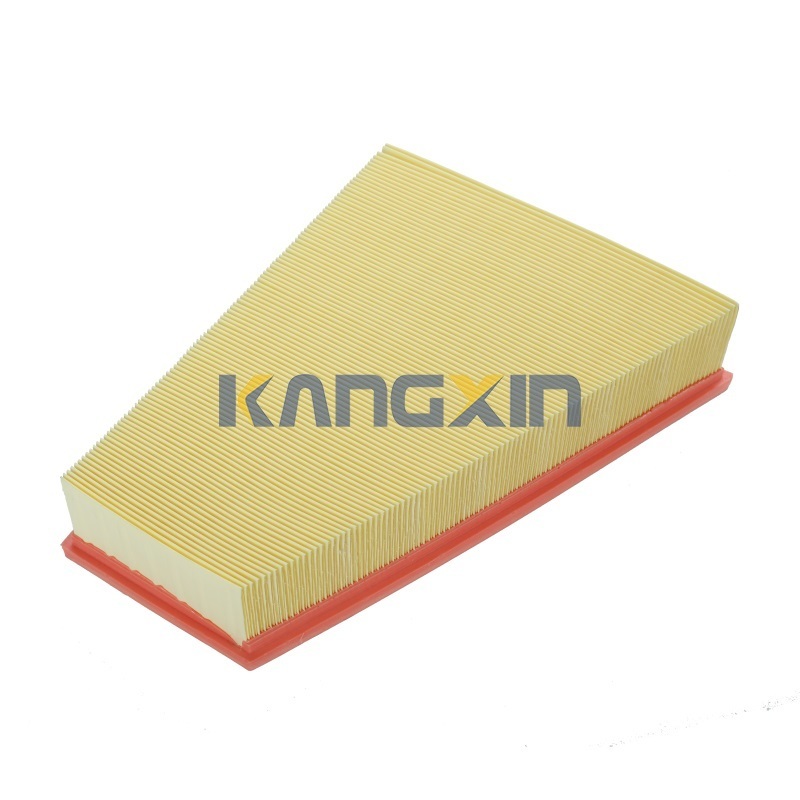

To maintain the cabin air filter for air conditioning in industrial equipment, it is recommended to follow the manufacturer's guidelines for filter replacement intervals. Additionally, inspecting the filter regularly for any signs of damage or clogging is crucial. If the filter appears dirty or worn out, it should be replaced immediately to prevent any potential issues with the air conditioning system.

Overall, ensuring the proper functioning of the cabin air filter is essential for maintaining a clean and healthy environment inside industrial equipment cabins. By understanding the importance of cabin air filters and following proper maintenance practices, operators can ensure the longevity and efficiency of their air conditioning systems.

Cabin air filters are designed to trap dust, pollen, and other airborne particles before they enter the air conditioning system. By doing so, they prevent these contaminants from circulating throughout the cabin, protecting both the equipment and the operators from potential health hazards. Regularly replacing the cabin air filter is important to ensure optimal performance and efficiency of the air conditioning system.

To maintain the cabin air filter for air conditioning in industrial equipment, it is recommended to follow the manufacturer's guidelines for filter replacement intervals. Additionally, inspecting the filter regularly for any signs of damage or clogging is crucial. If the filter appears dirty or worn out, it should be replaced immediately to prevent any potential issues with the air conditioning system.

Overall, ensuring the proper functioning of the cabin air filter is essential for maintaining a clean and healthy environment inside industrial equipment cabins. By understanding the importance of cabin air filters and following proper maintenance practices, operators can ensure the longevity and efficiency of their air conditioning systems.

Keywords:

More information